gCreate 2022 gMax Autumn / Winter Updates

- Gordon LaPlante

- Dec 15, 2022

- 4 min read

We have been very busy in 2022 and are excited to announce several new updates, features and products now available!

Firmware updates:

We have been extensively testing Marlin 2.1.1 firmware and have implemented several exciting new features. You can download the latest firmware update here.

Bed Leveling Changes

Introduction of Unified Bed Leveling (UBL) to replace Bi-Linear Bed Leveling (BBL). With the introduction of UBL we have also implemented high speed leveling mode and a new probing pattern. The result is a 60% reduction in probing time from 10:44 to around 4:23 minutes!

With the new firmware you can save up to 5 bed leveling meshes to memory allowing you to level the bed at different temperatures.

MPC replaces PID heating

Traditionally temperature control was handled by a PID algorithm. The new marlin utilizes a new heating method called Model Predictive Temperature Control (MPC).

The new heating algorithm controls the actual hotend temperature rather than the sensor temperature resulting in much more responsive temperature control.

In our tests, the new MPC heating will generally maintain a temperature within 0.2C!

To learn more:

Optimized Planner Motion, Arc Printing Changes and Linear Advance

Several PRs have been implemented optimizing how the planner calculations are handled resulting in simpler math and more time for the CPU to focus on other things. Small changes have also been made to the arc printing routines (G2 and G3) to improve quality and speed.

Arc printing has been supported on the gMax in earlier firmware releases as an experimental feature in anticipation of future slicer engines incorporating it.

We have implemented Linear Advance. Previous tests with LA resulted in poor quality and classic jerk was used instead. With the new changes and tweaks to the firmware corners are now sharper and quality is improved. We are also utilizing Junction Deviation for better extruder retraction and corner handling.

With all the changes, including new slicer profiles, overall quality of finished prints have increased!

Additional Features

Printer Stats

We have been able to re-implement the print timer so you can see your print stats. Previously, this feature had to be disabled but now it's back.

You can see your print stats from classic marlin mode (touch the screen for two seconds and select classic marlin). Then go to "Menu > About Printer > Print Stats". Note the stats only start when the new firmware is installed.

Event LEDs

The RGB LED bar on the printer now will show different colors depending on the status of the printer.

As the printer heats up at the beginning of a print, the lights will go from purple to red as it reaches temperature.

At the end of a print, if it was successful the light will be green.

If the printer has a warning, such as a filament run out, the light will go yellow.

If the printer had any errors the light will go red.

X-twist is reduced to 3 points instead of 4 thanks to the UBL improvements

Updated the firmware for the new SKR v3

More information on Marlin can be found here:

gMax 2 PRO Touchscreen Firmware Updates

Event LED's

Event led's now work with Marlin firmware

Preheating improvements

The printer will default to preheat the nozzle only, if the heated bed isn't detected.

Runout sensor is off warning when you start a print.

In case you have the runout sensor turned off, a warning will pop up allowing you to activate or ignore it so you don't have the filament runout without knowing the sensor is off.

Option to ignore heated bed if using acrylic

If you accidently left the heated bed on in your gcode but don't have the heated bed installed, the printer will ignore heated bed commands.

Speed improvements on screen refresh

New PrusaSlicer 2.5 Config Files

We have published new configuration files for PrusaSlicer 2.5 with dramatically reduce print time. If you are already using PS an update notification should pop up when you restart the program.

In some cases the print time was reduced by over 30%!

New Print Beds and Surfaces

Aluminum Reinforced Acrylic Bed

Our aluminum reinforced acrylic beds are now laser cut which means no more

bed clips are needed. A sanded acrylic sheet is adhered to a bent aluminum bed providing a very strong surface for your PLA prints.

We often print large parts that fit the entire print volume and large stresses are created causing the existing acrylic beds to slightly warm. These new beds will counteract those strong forces and don't require any heat!

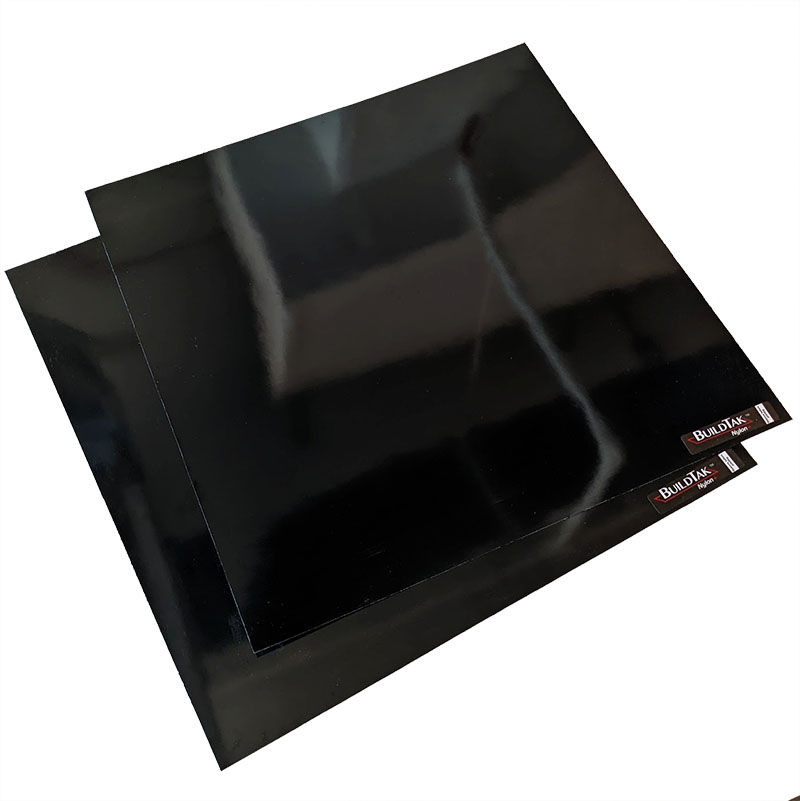

Nylon+ by BuildTak

Have you been printing a lot and need to replace your bed? We now offer replacement surfaces for our G10FR4 heated beds.

The Nylon+ sheets by BuildTak can be placed right on top of the bed and have adhesive on one side. The surface is the same as our G10FR4 and it's perfect for Nylon and PET prints.

New Material Testing

Braskem

Braskem is a Brazilian petrochemical company headquartered in São Paulo and they have several new filaments we have been experimenting with.

Bio EVA - Sustainably sourced from sugarcane, this new material is flexible and an alternative to TPU.

FL300PE - Polyethelyene filament with amazing strength and layer bonding.

FL500PP - Glass fiber reinforced polypropylene. Produces a great surface finish and results in a stable strong print.

FL900PP-CF - Carbon fiber reinforced polypropylene

FL105PP - Natural polypropylene that is lightweight and strong.

The Virtual Foundry

Filamet full metal filaments. TVF filaments are 90%+ metal and after debinding and sintering in a kiln, the result is a full metal part. Check out our 2 part article documenting our bronze and copper process.

Comments